Different display kit assembly

How does the different display kit assembly work?

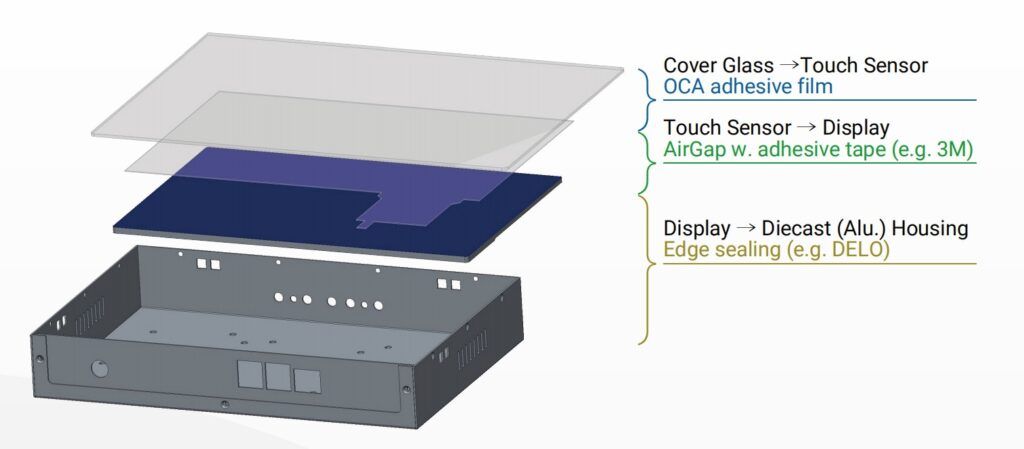

We integrate optical bonding technology into the seamless bonding process between the cover glass and the screen. Following this, the screen is securely affixed to the display using air gap and adhesive tape, such as 3M. This meticulous process is designed to optimize both the appearance and performance of the display devices.

Furthermore, in CSD assembly, the optically bonded CSD is assembled into a die-cast (aluminum) casing with edge sealing, employing methods like DELO. In the presence of circuit boards or mainboards, a precise connection is established with the display screen, ensuring flawless integration for the smooth operation of the entire system.

Quality in focus & excellence in details

GETT.EQUIPMENT

GETT.EXPERTISE

GETT.QUALITY

GETT.PRODUCTION

GETT.SUSTAINABLE

Our all-round carefree package for product development

Where else can we support you besides consulting?

We have customized our entire package for you. Our experts accompany you from the first consultation through development and network to the production of your product. You can also take individual packages.

LET's get in touch

We’d be happy to assist you – schedule an appointment with us, and our experts will be in touch!